Machine Vision System For Quality Evaluation

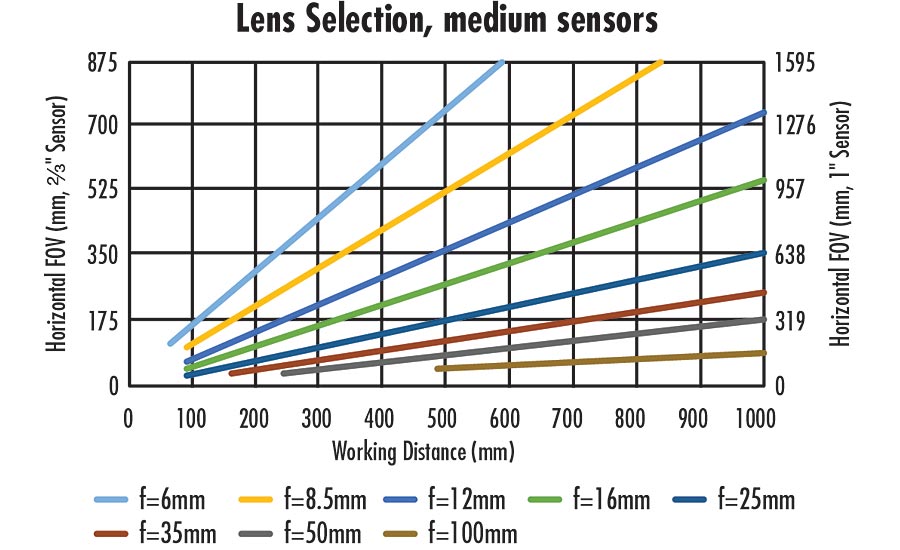

Verify that the lens and camera produce the correct FOV at the desired WD Confirm that the imaging system camera lens illumination create a high-quality contrast and feature definition image relative to the needs of the application. Machine vision system MVS is an image processinganalysis technique which is used for objective evaluation of quality parameters.

Lens Selection Guide Part 2 2018 12 01 Quality Magazine

Varies from person to person.

Machine vision system for quality evaluation. Some means of presenting the object to be inspected to. The obtained indexes given by a SC of an expert technician and the FLC using the machine vision system are given in Table 3. A value less than 1 means that the seedling has not germinated and a value greater than 4 is the ideal situation.

Machine vision systems are non-destructive non-contact and non-invasive methods of food grain quality evaluation. QUALITY EVALUATION USING MACHINE VISION Computer Machine vision system for quality evaluation of food products contains standard hardware configuration as shown in figure 21. In the external quality assessment using machine vision a good lighting system should provide uniform radiation throughout the scene avoiding the presence of glare or shadows and it must be spectrally uniform and stable over time.

These techniques particularly for fruits and vegeta-bles are quick and easy to use Jha and Matsuoka 2004. The approach can provide rapid and accurate information about external quality aspects of food grains. Its speed and accuracy satisfy ever increasing production and quality requirements hence aiding.

RNA automated vision inspection systems are designed to cater for a wide range of components and can be used for pharmaceuticals medical devices automotives system integrators machine builders sorting manufacturing packaging and all-type of automation and robotic applicationsThe systems have been developed to meet high speed quality control requirements for 100 inspection. Machine vision provides one alternative for an automated non-destructive and cost-effective technique to accomplish these requirements. Currently non-destructive quality evaluation techniques have gained momentum Iwamoto et al.

The ultimate goal of this project was to develop an efficient effective compact and robust machine vision system that is able to provide real time grain quality information to combine operators. This is one of the most challenging applications of computer technology. The current study represents a first phase in which the technical feasibility of grain quality monitoring using a front and back lighting based image acquisition system in combination with image processing.

This inspection approach based on image analysis and processing has found a variety of different applications in the food industry. The basic evaluation should achieve the following. A classification algorithm separated light from darkcolored muffins.

The systems precision was assessed by evaluating the color of 4 cm diameter muffins pregraded prior to the evaluation of color and without pregrading. Muffins were evaluated for color by visual examination and by development of a machinereading system coupled with discriminant analysis of the data acquired. The fruit produced in the farm is sorted according to quality and then transported to different standard markets at different distances.

It consists of. The developed machine vision system uses deep learningbased techniques that could accurately estimate cordon trajectories with root mean square error RMSE of 73 103 and 161 pixels for canopy images captured in 24 weeks of shoot growth respectively. Machine vision and image processing techniques have been found increasingly useful in the fruit industry especially for applications in quality inspection and defect sorting applications.

Scope and approach Machine vision systems have the potential to replace manual visual methods of inspection and have therefore gained wide acceptance in industries as a tool for quality evaluation of numerous agricultural products. Evaluation Engineering Sep 1st 2001 Machine vision allows you to obtain useful information about physical objects by automating analysis of digital images of those objects. Comparison of the results shows that the differences between the two indexes are about 05 which is a small value taking into account the discretisation in.

Conventional method of grain quality evaluation visual inspection a manual method is challenging even for trained personnel in terms of rapidity reliability and accuracy. Jha and Matsuoka 2000 and machine vision system provides a means to perform entire tasks automatically Diaz et al.

Book Of The Week Close Range Photogrammetry And 3d Imaging Fabbaloo Book Week Aerial Photography Image Processing

Machine Vision Vs Computer Vision What S The Difference

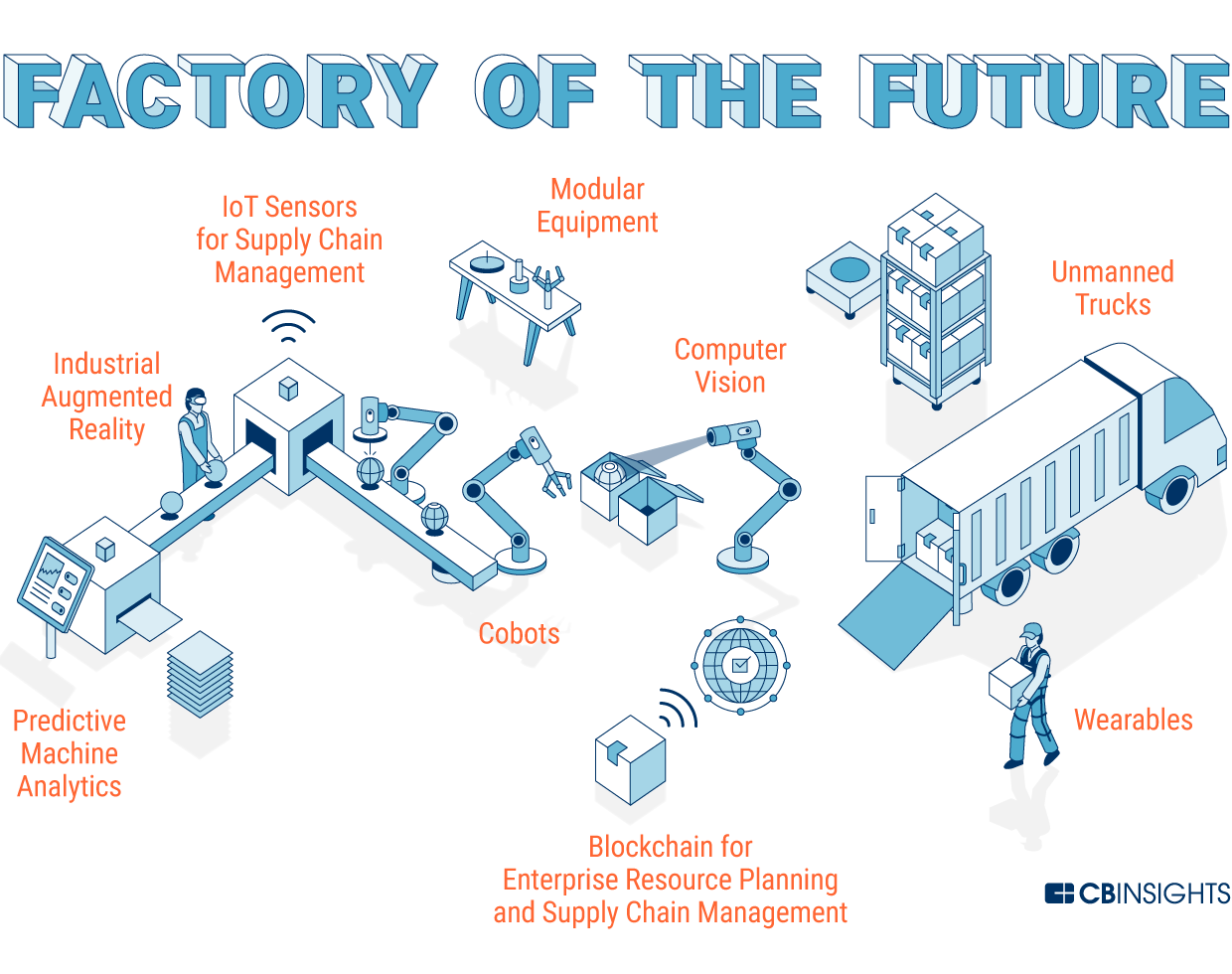

The Future Of Manufacturing Technology L Cb Insights

Automotive Metal Industries Vhx 600 Microscopes Materials Engineering Metal Microscopic

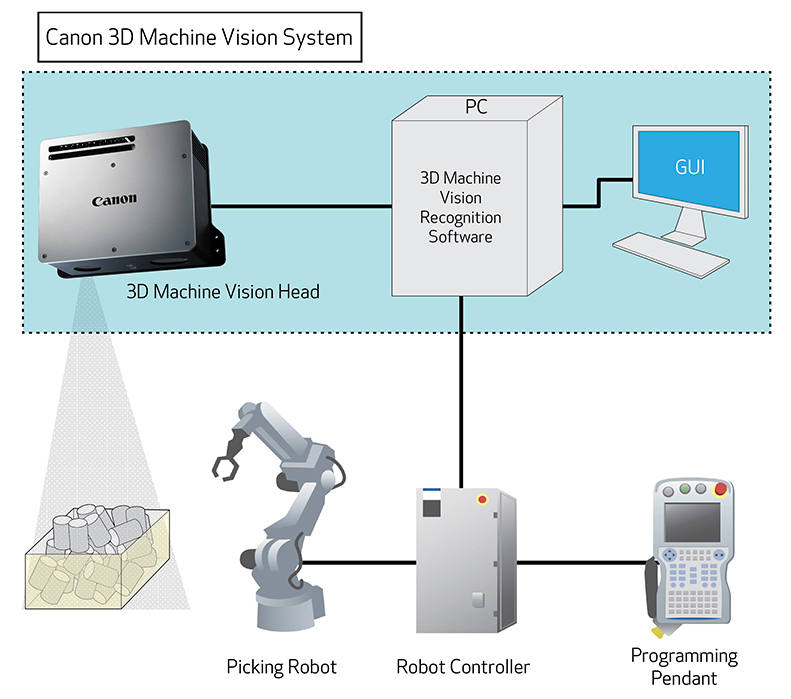

Canon U S A Inc 3d Machine Vision System Bin Picking System

8 Connected Patterns Machine Learning Design Patterns Learning Design Machine Learning Pattern Design

Canon U S A Inc 3d Machine Vision System Bin Picking System

As The Manufacturing Industry Becomes More Competitive Ensuring Products Are Of The Highest Standard Is Key To Acquiring New Custome Inspect Solutions Visions

Pharma 4 0 And Impact In Quality The Vision For Industry 4 0 Is To Associate All Assets Like Human Data And Physical M Pharma Physics Pharmaceutical Industry

Cogito Tech Provides Visual Search Solution For Ecommerce And Other Online Searchers To Utilize The Image Visual Search Technolo Deep Learning Visual Learning

Computer Vision Industrial And Logistics Applications By Kate Lyapina Zyfra Medium

Computer Vision System And Near Infrared Spectroscopy For Identification And Classification Of Chicken With Wooden Breast And Physicochemical And Technological Characterization Sciencedirect

Nine Core Elements Of A Quality Management System Management Organizational Structure System

Robot Vision Products Robots For Vision Inspection Systems Fanuc Irvision

Irjet Quality Inspection Of Tire Using Deep Learning Based Computer Vision Deep Learning Computer Vision Teaching Programs

Maximize Existing Vision Systems In Quality Assurance With Cognitive Ai Cognitive Legacy System Quality Assurance

Deep Learning For Visual Search Evaluation Deep Learning Visual Learning

Stereo Vision Evaluation System Home Evaluation System Read Image University Of Delaware

Sensors Free Full Text Applications Of Non Destructive Technologies For Agricultural And Food Products Quality Inspection Html

Post a Comment for "Machine Vision System For Quality Evaluation"